- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Parking in cities is getting harder every year. Streets are crowded and space is expensive. What if smart machines could solve this? Automated parking systemsmake every inch count. They store and retrieve cars safely and fast. In this post, you’ll learn how these systems work and why they’re changing urban parking forever.

Imagine driving into a building and leaving your car at the entrance — no ramps, no hunting for space.

A fully automated parking system (APS) does the rest. It moves, stores, and retrieves vehicles automatically using machines instead of people.

It’s simple on the surface but smart underneath.

Here’s what happens step by step:

Arrival & Scanning – The driver parks in an entry bay. Sensors measure the car’s size and weight.

Transfer – Once confirmed, the platform lifts or slides the car into storage.

Storage – Robots or conveyors place vehicles in compact rows or racks.

Retrieval – When requested, the system returns the car to the driver—front out, ready to go.

Below is a basic process flow:

| Stage | Action | Technology Used |

|---|---|---|

| Entry | Driver positions car in bay | Laser sensors, display guides |

| Transfer | Car lifted or shifted | Hydraulic lifts, shuttles |

| Storage | Vehicle placed in slot | Rails, conveyors, robotic arms |

| Retrieval | Car brought back | Computerized control, queue system |

An APS blends mechanics and software into one smart unit.

It usually includes:

Transfer Cabin – Where the car enters or exits.

Vertical Lifts – Move cars between levels.

Shuttle or Conveyor Units – Carry cars horizontally.

Control System – Manages commands and prevents collisions.

Sensors & Cameras – Check dimensions and ensure safety.

Each part works like a team member—fast, precise, and synchronized.

Not all systems are the same. They vary in design and purpose.

These use small carriers to move cars sideways and store them on racks.

They’re perfect for large garages or rectangular spaces needing hundreds of slots.

Cars sit on pallets that slide across conveyors.

This method uses every inch of floor space—ideal for mid-size buildings and public areas.

A vertical carousel lifts cars like an elevator.

It’s compact and efficient, often seen beside office towers or narrow urban lots.

Platforms rise, drop, or shift to create free spaces.

It’s a simpler version, great for smaller properties wanting automation at lower cost.

They solve problems cities face daily — not enough space, too many cars.

By removing ramps and drive lanes, APS reduces land use by up to 60%.

It also cuts emissions since engines stay off while parking.

People spend less time circling lots.

Developers save money on concrete and ventilation.

Everyone wins — cleaner air, smarter design, faster parking.

| Feature | Traditional Garage | Automated Parking System |

|---|---|---|

| Space Use | Needs ramps and lanes | Uses vertical stacking |

| Time | Long search and exit | Automated retrieval |

| Safety | Risk of theft or scratches | Enclosed and monitored |

| Cost | High build and land cost | Efficient, smaller footprint |

| Eco Impact | More CO₂ from idling | Reduced emissions |

Mutrade builds different automated parking systems for all kinds of spaces and budgets.

Each design focuses on saving land, cutting costs, and making parking simple for users.

Let’s look at the main types Mutrade offers and how they work in real life.

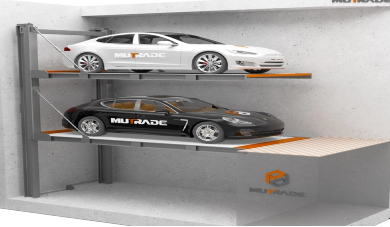

These are Mutrade’s most popular mechanical parking lifts.

They use hydraulic cylinders to raise and lower vehicles, creating two or more parking levels in the same footprint.

Perfect for homes, offices, or small commercial spaces—it’s like stacking cars safely in the air.

Every platform holds one car; the lower car must be removed before the upper one comes down.

Key Features:

Simple structure, easy to install

Low noise operation

Cost-effective for limited spaces

Compatible with sedans and small SUVs

| Model Example | Levels | Operation Type | Best For |

|---|---|---|---|

| Hydro-Park 1127 | 2 | Hydraulic lift | Private garages |

| Starke 2127 | 2-4 | Pit or above ground | Condominiums |

| Starke 3121/3127 | 3 | Wide-deck pit lift | Underground parking |

These systems work best when users want affordable, semi-automated solutions that maximize capacity without heavy machinery.

The BDP Series—often called “puzzle parking”—uses a grid of movable platforms.

Cars shift horizontally and vertically until an empty space opens for retrieval.

It’s like watching cars slide in a smart dance routine.

Mutrade’s puzzle parking systems handle anywhere from 5 to 50 vehicles, depending on the layout.

Advantages:

Fully automatic parking and retrieval

No ramps or wide aisles needed

Great use of underground or above-ground areas

Optional pit structures for multi-level designs

This setup suits apartments, shopping centers, or mixed-use buildings where every square meter matters.

When land is tight but vertical space is plenty, the ARP Series shines.

This rotary or tower system works like a vertical carousel—cars rotate around a central axis until yours appears at ground level.

Drivers park at one entrance bay; the system rotates to lift the car upward automatically.

Highlights:

Up to 16 cars per tower

Compact footprint—ideal for narrow city lots

Quick retrieval time (under 90 seconds)

Fully enclosed for safety and weather protection

| Parameter | Description |

|---|---|

| Space Needed | Approx. two standard parking spots |

| Power Type | Motor-driven chain system |

| Capacity | 6–16 cars |

| Use Case | Urban offices, hotels, retail zones |

People love this system because it’s quiet, fast, and fun to watch in action.

These systems use automated shuttles that move cars horizontally and vertically on rails.

Each car sits on a metal pallet, and the shuttle carries it to a free slot.

They offer high speed, high capacity, and extreme efficiency for large buildings.

Ideal for:

Shopping malls

Airports

Corporate campuses

Large residential complexes

Technical Edge:

Multi-level storage using shuttles and lifts

Centralized control for real-time management

Advanced safety sensors and redundancy systems

Compared to lifts or rotary units, shuttle systems handle hundreds of vehicles at once while reducing waiting times.

Mutrade understands that no two projects are the same.

Their custom modular systems combine hydraulic, rotary, or shuttle technologies to fit unique architectural needs.

The company designs solutions based on:

Site dimensions and load limits

Local building regulations

Vehicle mix (cars, SUVs, EVs)

Aesthetic and access requirements

Custom modules let architects and developers integrate parking directly into their building design—above ground, underground, or both.

| System Type | Mechanism | Capacity Range | Best For | Key Benefit |

|---|---|---|---|---|

| Hydraulic & Starke Lifts | Vertical lifting | 2–3 cars | Homes, offices | Low-cost expansion |

| Puzzle (BDP) | Sliding platforms | 5–50 cars | Apartments | Compact automation |

| Rotary (ARP) | Rotating tower | 6–16 cars | Urban lots | Uses vertical space |

| Shuttle Systems | Rail + shuttle | 50+ cars | Malls, airports | Fast retrieval |

| Modular Systems | Mixed tech | Custom | Any project | Fully adaptable |

Mutrade stands out for three key reasons: innovation, precision, and service.

The company continuously improves its technologies and manufacturing processes. Their factory uses robotic welding, CNC machining, and quality-assured assembly. This ensures every parking system meets strict performance and safety standards.

Mutrade’s experienced engineering team provides end-to-end solutions — from concept design and structural calculation to installation and maintenance. With projects in over 90 countries, their reputation for reliability and service is well established.

Mutrade’s Promise:

We provide the most complete and suitable parking solutions with advanced technology, accuracy, and strong service support.

Mutrade systems include safety backups and manual override features, ensuring vehicles can be retrieved safely even during outages.

Typically between 60 to 120 seconds, depending on system size and number of active users.

Most passenger cars, sedans, and small SUVs fit easily. Systems are designed with precise measurements to accommodate standard vehicle profiles.

Minimal. Mutrade’s hydraulic and mechanical components are designed for durability and require only periodic checks.

Yes. With sensor checks, secure doors, and automatic locking, Mutrade’s APS keeps both vehicles and people safe from harm.

Residential Buildings: Maximize parking capacity for apartments and condos.

Office Complexes: Provide seamless parking for employees and visitors.

Public Garages: Increase parking availability in crowded city centers.

Hotels & Airports: Offer premium, time-saving parking experiences.

Car Dealerships: Display and store vehicles efficiently in limited space.

Mutrade’s wide product range ensures a fit for every application — whether underground, above ground, or hybrid solutions.

Before installation, Mutrade’s engineers conduct site evaluations to determine:

Building footprint and available height

Load-bearing structure and pit depth

Power supply and ventilation needs

Access routes for vehicles and users

Once the plan is finalized, prefabricated components are quickly assembled on site. This reduces construction time and disruption — a key benefit of Mutrade’s modular design.

Money matters when planning a new parking project.

Many people ask—is an automated parking system really worth it?

Let’s break down how costs work and where the return on investment (ROI) truly shines.

Automated parking systems (APS) require more technology than traditional garages, but they use less land and structure.

So while the upfront cost per space can be higher, the total project cost often ends up lower.

| Expense Type | Traditional Garage | Automated Parking System |

|---|---|---|

| Construction Materials | High (ramps, concrete) | Lower (compact structure) |

| Land Purchase | Large footprint | Smaller footprint |

| Labor & Time | Long installation | Shorter construction period |

| Equipment & Tech | Minimal | Robotics, sensors, lifts |

| Maintenance Setup | Basic | Advanced but efficient |

Mutrade’s modular design helps reduce overall cost.

Most systems use prefabricated steel frames, robotic welding, and fast on-site installation, cutting time and labor expenses dramatically.

Once installed, APS runs cheaper than conventional garages.

No attendants. No endless lighting or ventilation costs. No driving lanes to clean.

Here’s how savings add up:

Lower energy consumption since cars don’t idle inside.

Minimal staffing needs—automated control manages everything.

Less wear on structural parts thanks to precise mechanical movement.

Reduced insurance costs because accidents and theft are rare.

A study from automated garage projects shows up to 40% lower yearly operating costs compared to ramp-based facilities.

Mutrade systems are designed for easy maintenance—grease once, inspect sensors, and keep it running smoothly.

Land is money.

That’s where automated parking truly wins.

By removing ramps and access aisles, APS can fit up to 60% more vehicles in the same area.

| Factor | Traditional Garage | Automated Parking System |

|---|---|---|

| Cars per 1,000 m² | 100 | 160 |

| Ramp & Driveway Area | 35–40% of space | 0–10% |

| Height Requirement | 2.4 m per level | 1.8–2 m per level |

| ROI per m² | Medium | High |

For developers, that means more revenue per square meter—either from extra parking fees or additional leasable space for shops or offices.

APS literally pays for itself by freeing valuable floor area.

Traditional parking structures can take months or even years to complete.

Mutrade’s modular systems, built from pre-engineered components, cut that timeline by up to 50%.

Less construction time = earlier opening = faster income generation.

It also means lower financing costs, as loans start producing returns sooner.

Investors and property owners benefit beyond immediate savings.

Buildings equipped with APS tend to have higher property values due to modern infrastructure and sustainable appeal.

Developers also find it easier to obtain building permits, especially in dense urban zones where space limits apply.

For high-end projects, an APS can even serve as a luxury feature—adding status to the property.

In short:

Higher resale value for smart, sustainable properties

Increased tenant satisfaction and occupancy rates

More efficient use of every square meter

| Scenario | Traditional Garage | Automated System |

|---|---|---|

| Project Area | 1,000 m² | 1,000 m² |

| Parking Capacity | 100 cars | 160 cars |

| Avg. Fee per Car / Month | $150 | $150 |

| Monthly Income | $15,000 | $24,000 |

| Annual Income | $180,000 | $288,000 |

| ROI Period | 9–10 years | 5–6 years |

Even after factoring in installation costs, the payback period shortens significantly when land savings and higher capacity are considered.

Developers get faster returns.

Users get easier parking.

Cities get smarter, cleaner structures that last decades.

When selecting an APS, consider:

Capacity needs – how many vehicles to store

Available land area and height

Vehicle mix – cars, SUVs, or electric vehicles

User frequency – residential vs commercial use

Budget and project timeline

Mutrade offers consultation and customized system design. Their engineers evaluate your project’s parameters to ensure the most cost-effective and technically sound solution.

Automated parking systems are more than an engineering innovation — they represent a shift toward smarter, more sustainable urban living.

Mutrade’sautomated parking solutions deliver reliability, precision, and efficiency for developers worldwide. Whether you’re planning a new building or modernizing an existing one, investing in Mutrade’s APS means unlocking valuable space, enhancing property value, and improving user experience.

The future of parking is automated — and Mutrade is leading the way.