- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

BDP-2

Mutrade

BDP-2

Bi-Directional Parking System 2 Levels

Introduction

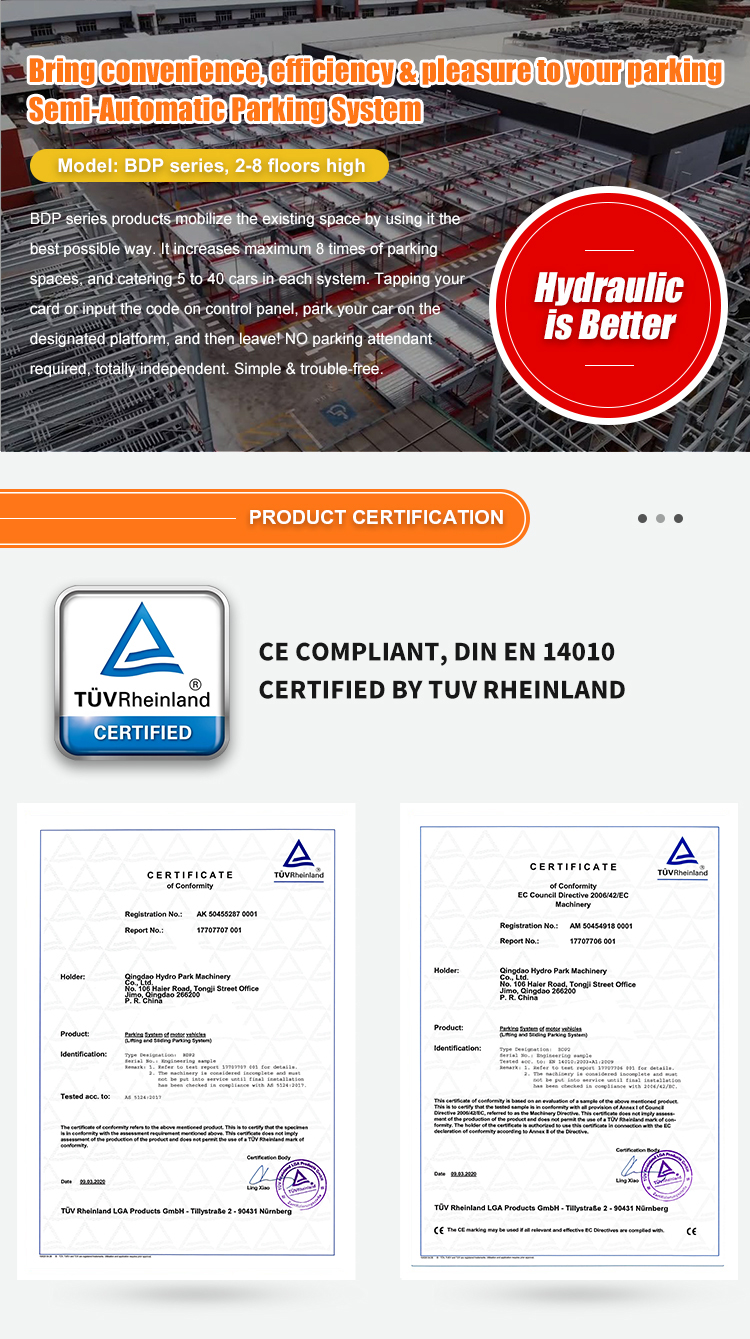

BDP-2 is a semi-automatic parking system, developed by Mutrade. The parking space selected is moved to the desired position by means of an automatic control system, and the parking spaces can be shifted vertically or horizontally. Entrance level platforms move horizontally and upper level platforms move vertically, with always one platform less at the entrance level. By swiping the card or input the code, the system automatically moves the platforms in the desired position. To collect a car parked on the upper level, the platforms at the entrance level will first move to one side to provide an empty space into which the required platform is lowered.

-Independent parking in 2 levels above each other -Multi size options corresponding to car heights, car widths and platform loadings

-2000kg capacity for sedan system, and 2500kg capacity for SUV system

-Easy operation and parking comfort

-High level of operating and functional safety

-Low-wear, low-noise proven hydraulic systems

-Galvanized platform with wave plates for better parking

-High elevating speed to reduce waiting time

-Central hydraulic power pack and control panel, with PLC control system inside

-Code, IC Card and manual operation available

-Reliable mechanical anti

-falling protection

-Hydraulic overloading protection

-Optional safety gates at access level protect cars against theft and vandalism.

| Model | BDP-2 |

| Levels | 2 |

| Lifting capacity | 2500kg / 2000kg |

| Available car length | 5000mm |

| Available car width | 1850mm |

| Available car height | 2050mm / 1550mm |

| Power pack | 4Kw hydraulic pump |

| Available voltage of power supply | 200V-480V, 3 Phase, 50/60Hz |

| Operation mode | Code & ID card |

| Operation voltage | 24V |

| Safety lock | Anti-falling frame |

| Rising / descending time | <35s |

| Finishing | Powdering coating |

BDP-2

Bi-Directional Parking System 2 Levels

Introduction

BDP-2 is a semi-automatic parking system, developed by Mutrade. The parking space selected is moved to the desired position by means of an automatic control system, and the parking spaces can be shifted vertically or horizontally. Entrance level platforms move horizontally and upper level platforms move vertically, with always one platform less at the entrance level. By swiping the card or input the code, the system automatically moves the platforms in the desired position. To collect a car parked on the upper level, the platforms at the entrance level will first move to one side to provide an empty space into which the required platform is lowered.

-Independent parking in 2 levels above each other -Multi size options corresponding to car heights, car widths and platform loadings

-2000kg capacity for sedan system, and 2500kg capacity for SUV system

-Easy operation and parking comfort

-High level of operating and functional safety

-Low-wear, low-noise proven hydraulic systems

-Galvanized platform with wave plates for better parking

-High elevating speed to reduce waiting time

-Central hydraulic power pack and control panel, with PLC control system inside

-Code, IC Card and manual operation available

-Reliable mechanical anti

-falling protection

-Hydraulic overloading protection

-Optional safety gates at access level protect cars against theft and vandalism.

| Model | BDP-2 |

| Levels | 2 |

| Lifting capacity | 2500kg / 2000kg |

| Available car length | 5000mm |

| Available car width | 1850mm |

| Available car height | 2050mm / 1550mm |

| Power pack | 4Kw hydraulic pump |

| Available voltage of power supply | 200V-480V, 3 Phase, 50/60Hz |

| Operation mode | Code & ID card |

| Operation voltage | 24V |

| Safety lock | Anti-falling frame |

| Rising / descending time | <35s |

| Finishing | Powdering coating |