- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HP1123 / HP1127

Mutrade

Hydro-Park 1127/1123

Two Post Parking Lift

Introduction

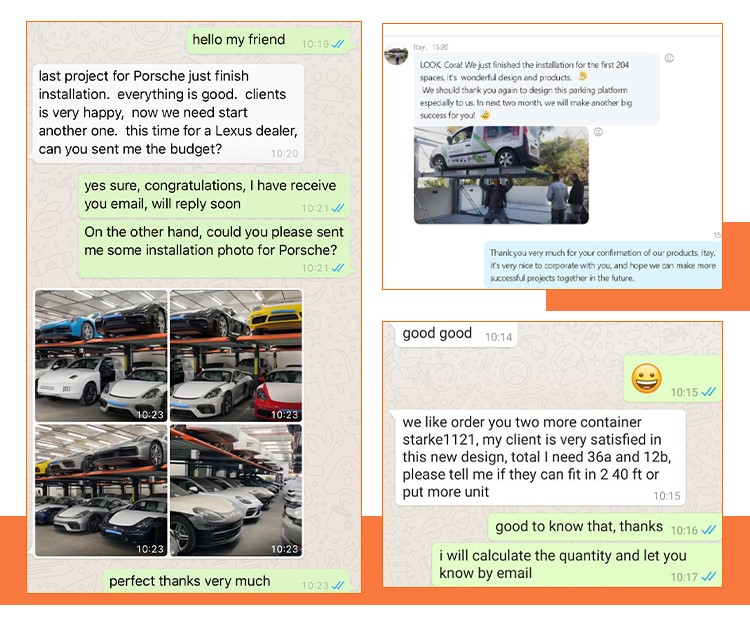

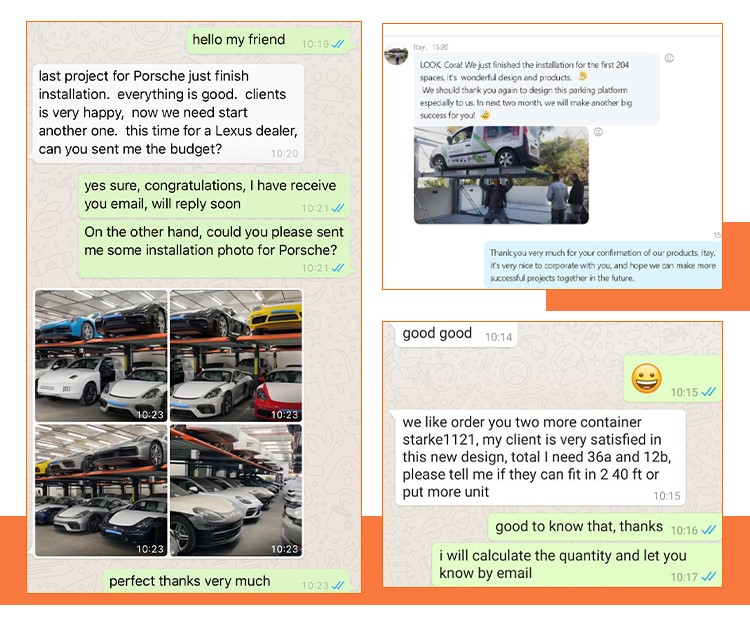

Hydro-Park 1127 & 1123 are the most popular parking stackers, quality proven by more than 20,000 users in past 10 years. They provide a simple and greatly cost-effective way to create 2 dependent parking spaces above each other, suitable for permanent parking, valet parking, car storage, or other places with attendant. Operation can be easily made by a key switch panel on control arm.

- Lifting capacity 2700kg or 2300kg.

- Car heights on ground up to 2050mm.

- Platform width up to 2500mm.

- Lifting height adjustable by limit switch

- Electric auto lock release enables easier operation.

- 24v control voltage avoids electric shock

- Galvanized platform, high-heel friendly

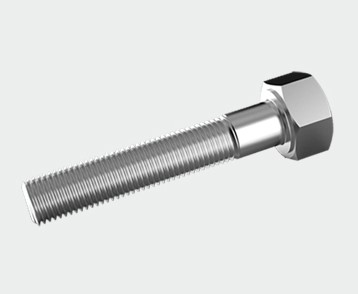

- Bolts & nuts passing 48hrs Salt Spray Test.

- Driven by hydraulic cylinder + Korean lifting chain

- Synchronization chain keeps platform level under all conditions

- Akzo Nobel powder coating provides long lasting surfificial protection

- Proven high end quality with CE certifificate, tested by TUV.

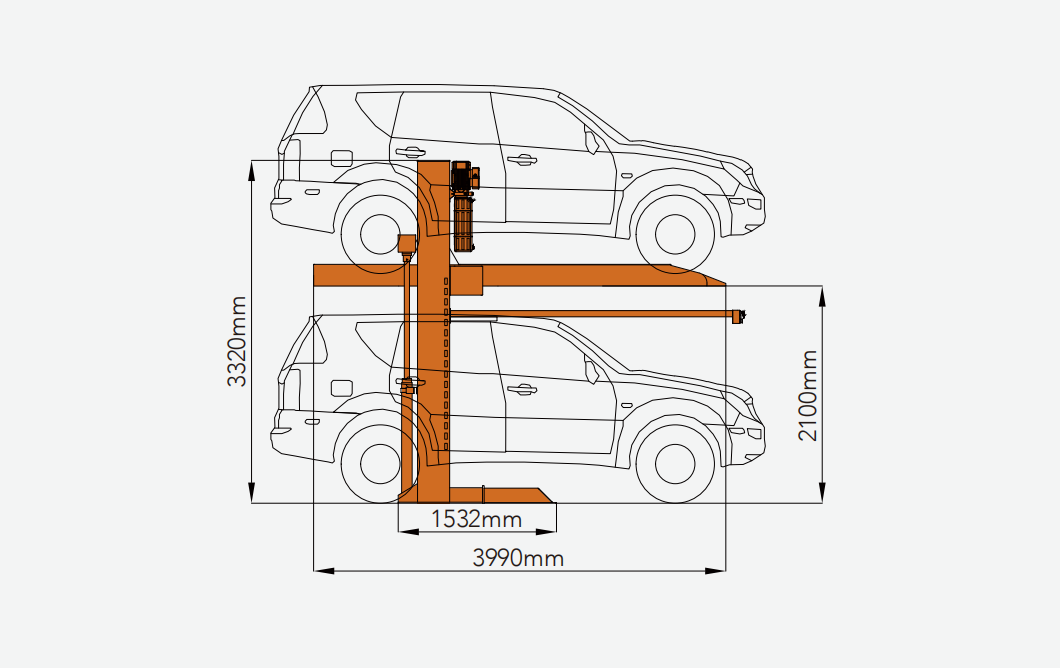

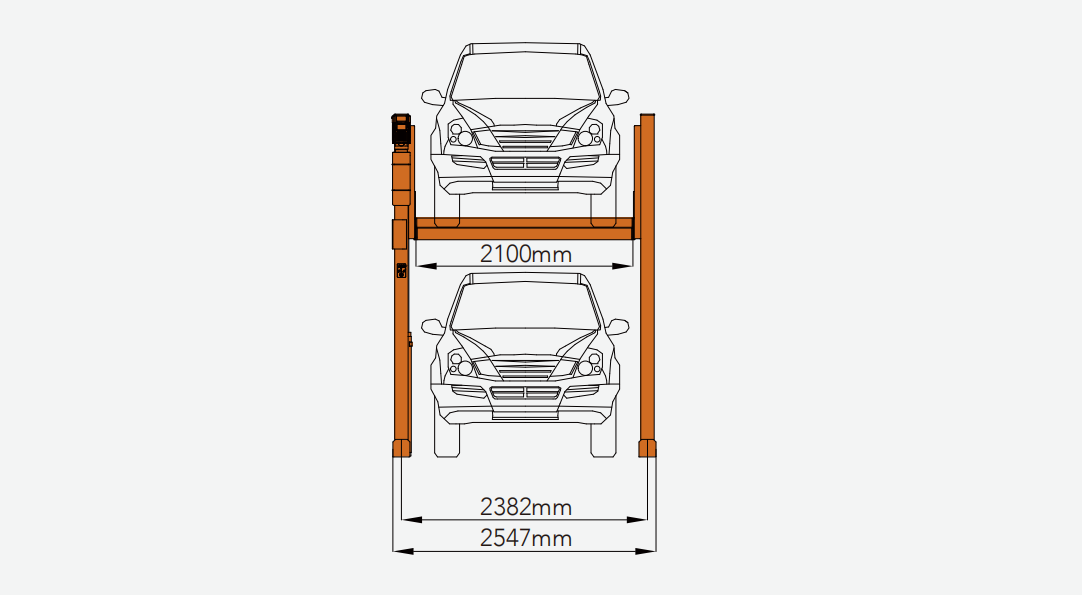

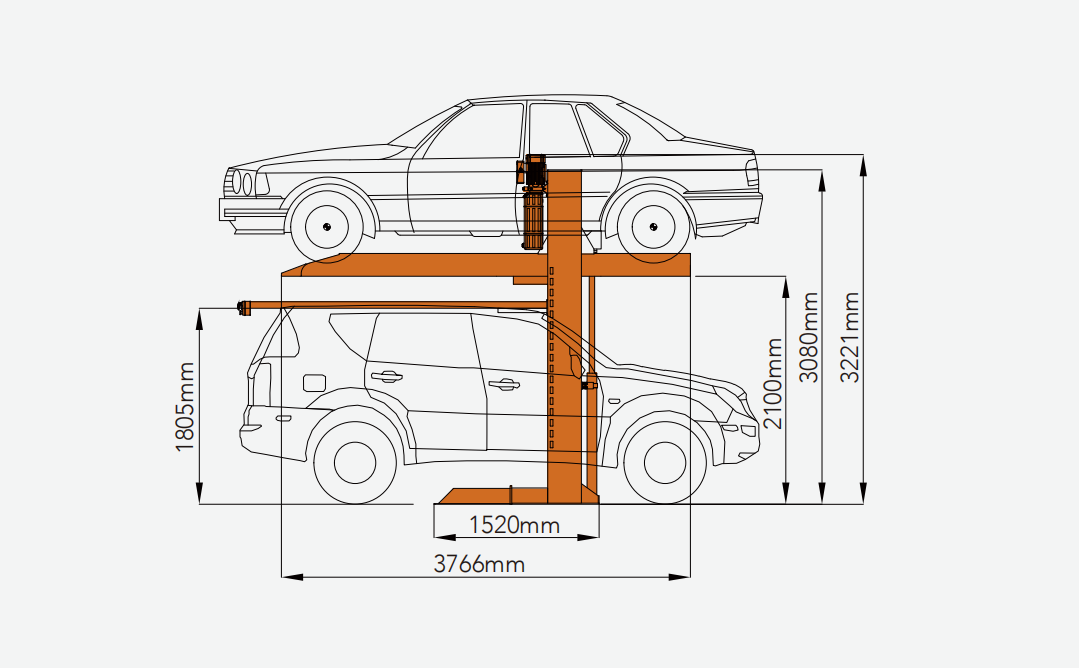

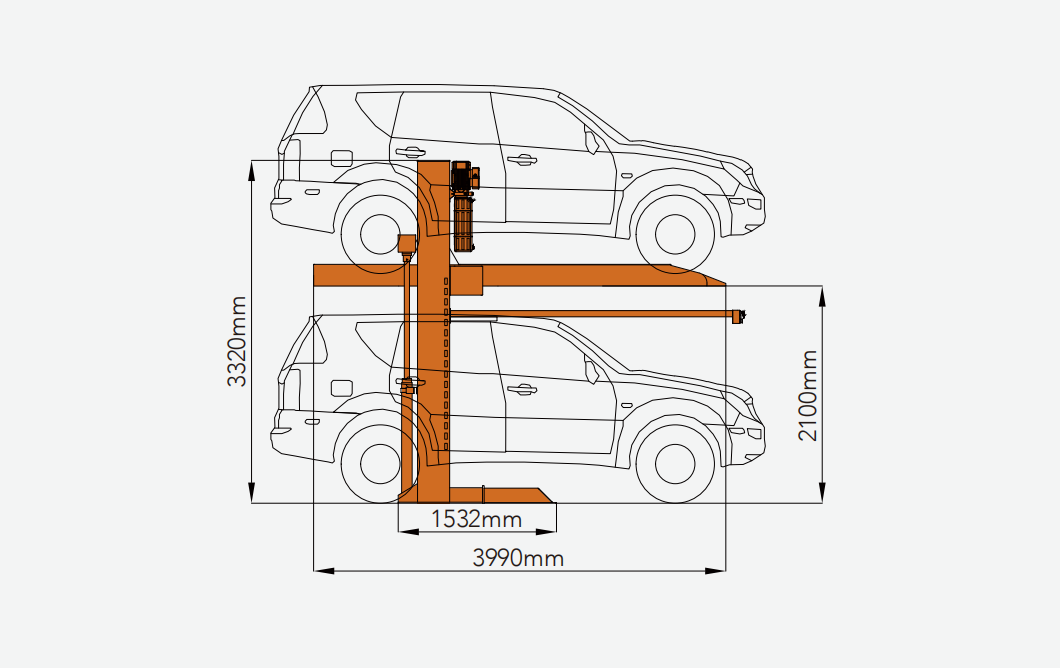

| Model | Hydro-Park 1127 | Hydro-Park 1123 | Hydro-Park 1120 |

| Lifting capacity | 2700kg /6000lbs | 2300kg /5000lbs | 2000kg/4400lbs |

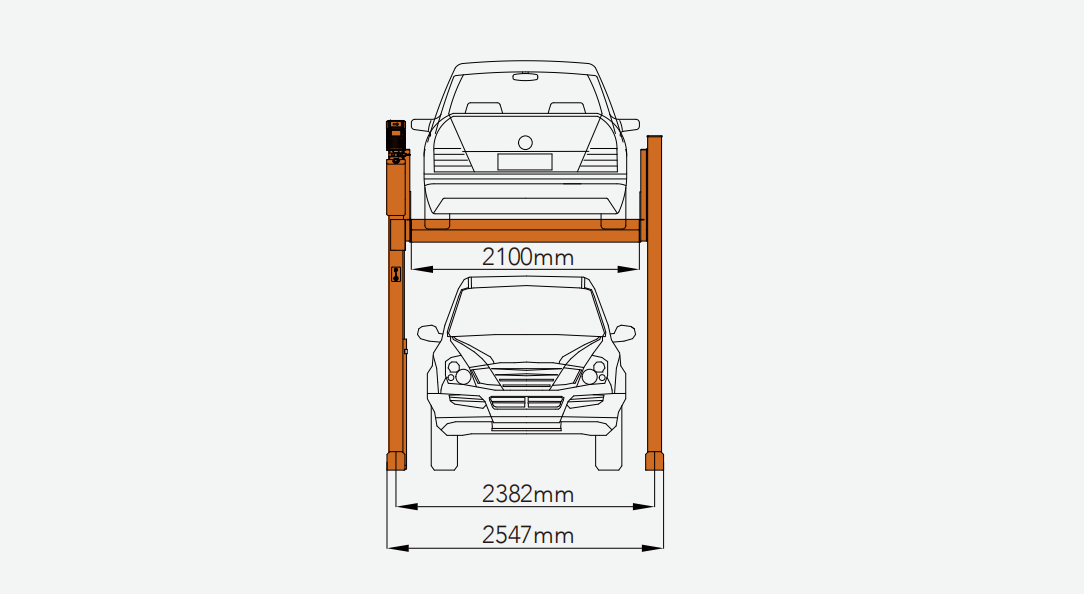

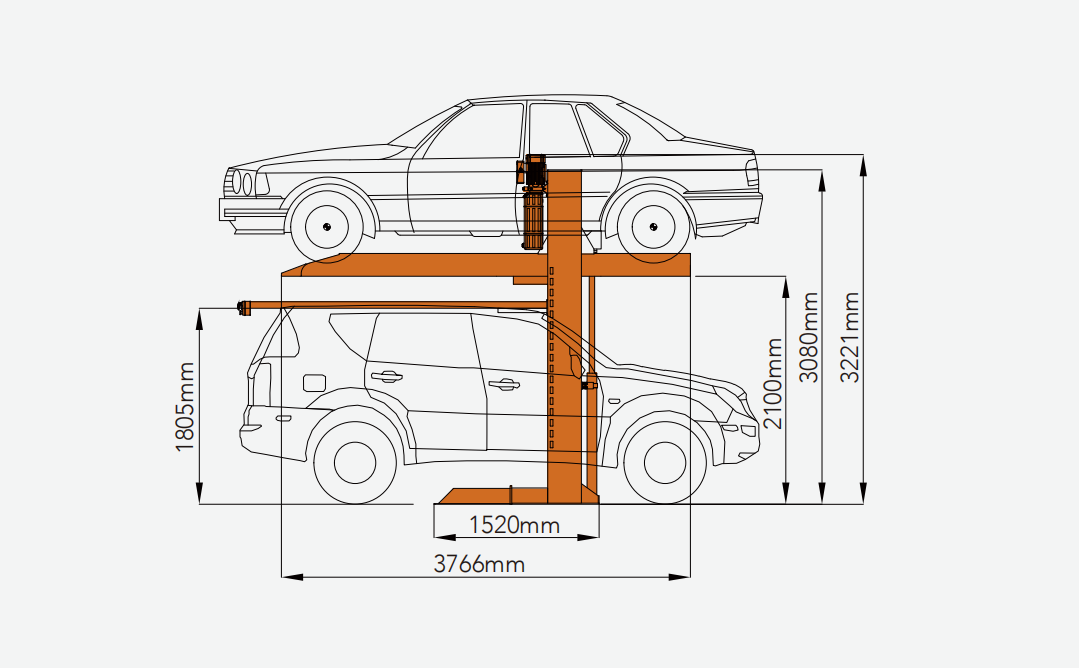

| Lifting height | 2100mm /6'10" | 2100mm /6'10" | 1850mm /6'1" |

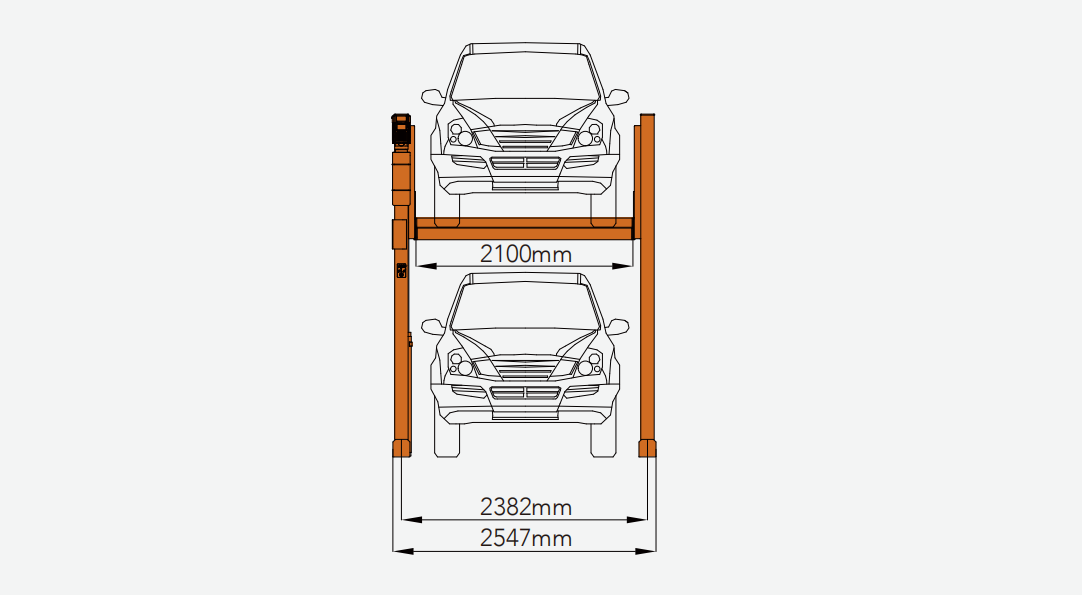

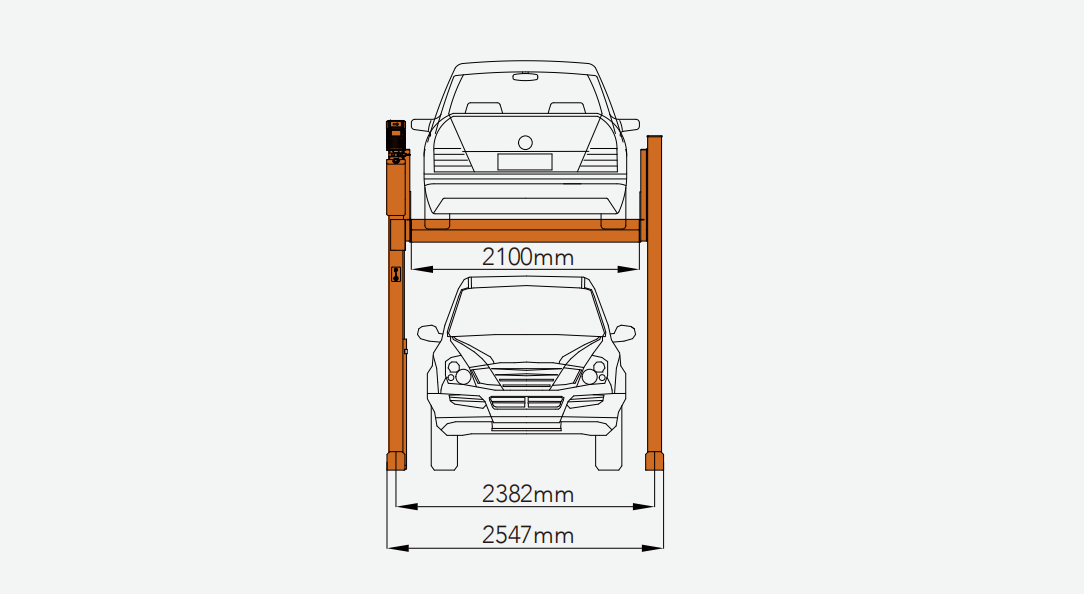

| Usable platform width | 2100mm /6'10" | 2100mm /6'10" | 2200mm /7'3" |

| Outer width | 2547mm /8'4" | 2547mm /8'4" | 2540mm /8'4" |

| Application | SUV+SUV | SUV+Sedan | Sedan+Sedan |

| Power pack | 2.2Kw | ||

| Power supply | 100-480V, 50/60Hz | ||

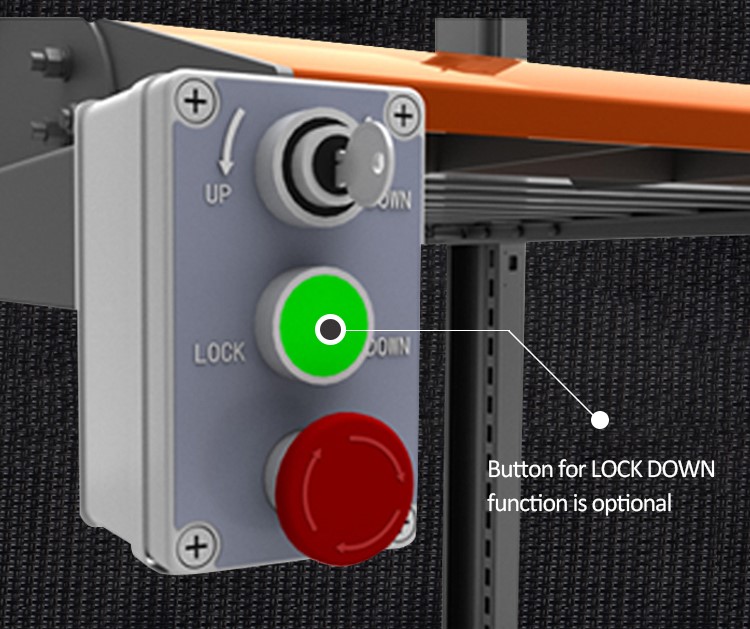

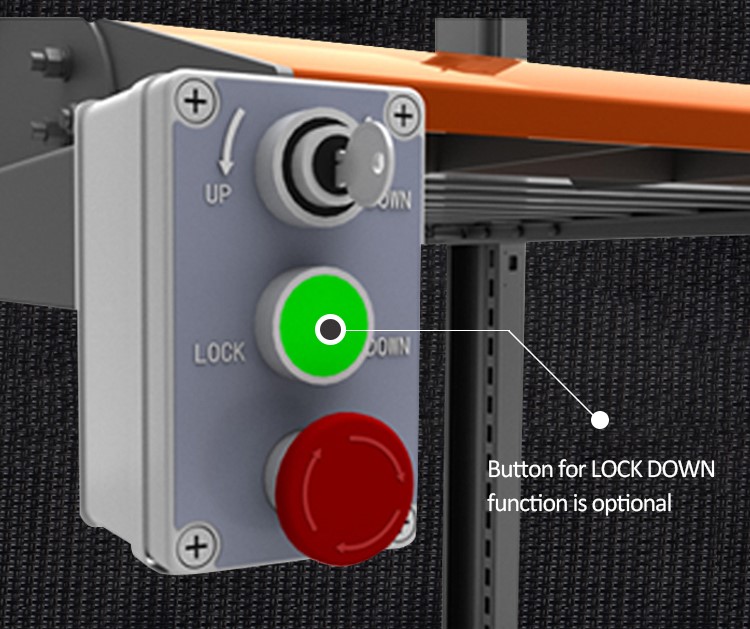

| Operation mode | Key switch | ||

| Operation voltage | 24V | 24V | 220v |

| Safety lock | Dynamic anti-falling lock | Dynamic anti-falling lock | Positioning lock |

| Lock release | Electric auto release | ||

| Lifting time | <55s | <55s | <35s |

| Finishing | Powdering coating | ||

Model HP1123 / HP1127

Model HP1123 / HP1127

This parking lift is hydraulic driven, with simple and reliable structure. The features of easy operation and long service life make it widely welcomed by families, enterprises, auto manufacturing, and auto logistics companies, etc.

The largest manufacturer of simple car parking lifts in China

Professional Experienced Highly-responsible

TUV Rheinland

CE COMPLIANT, DIN EN 14010

CERTIFIED BY TUV RHEINLAND

Two capacity options: 2300kg or 2700kg

Lifting height adjustable according to ceiling height

Keyswitch/emergency stop button

Concrete slab acceptable

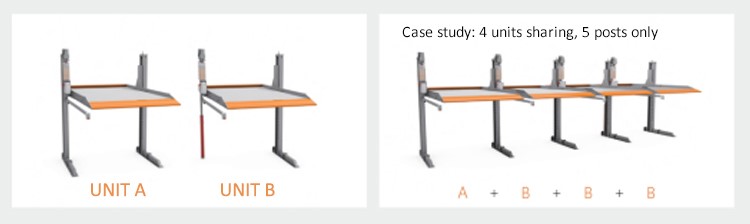

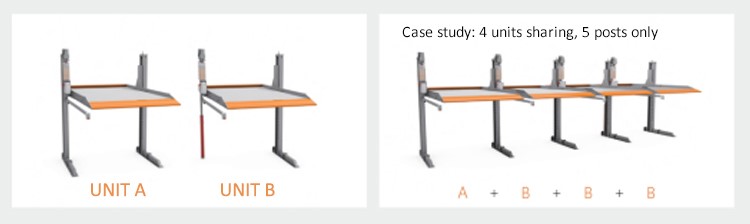

Case study: 4 units sharing, 5 posts only

Posts of HP1123 & HP1127 are designed symmetrically and can be shared by adjacent parking lifts.

When multiple lifts are installed and connected side by side, the first lift has complete structure (Unit A).

The rest unit(s) are incomplete and have one post only (Unit B), because they can borrow the right post of

former lift.

By sharing the post, they cover smaller area, enjoy stronger structure, and bring costs down.

Please check with our sales whether your site is suitable for post sharing and how much you can savel

The details are impeccable

01

UPGRADED &

THICKENED STEEL

Super strong structure with 5 years warrar

02

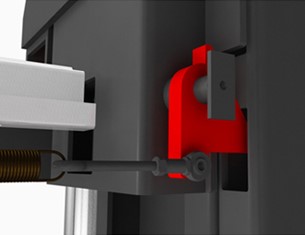

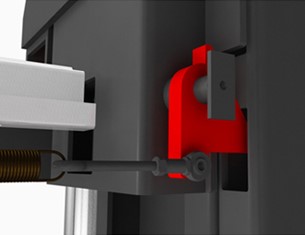

ANTI-FALLING LOCKS

MECHANICAL & SAFER

Protecting your vehicles all the way

up and down

03

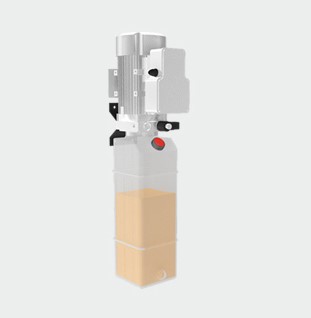

NEWLY UPGRADED

POWER PACK

24v control voltage, ZERO risk of electric

shock

04

STRONGER CHAINS

MADE IN KOREA

Withstanding 7 times of rated capacity

05

05

PASSING 72 HRS

SALT SPRAY TEST

Excellent rust resistance

Hydro-Park 1127/1123

Two Post Parking Lift

Introduction

Hydro-Park 1127 & 1123 are the most popular parking stackers, quality proven by more than 20,000 users in past 10 years. They provide a simple and greatly cost-effective way to create 2 dependent parking spaces above each other, suitable for permanent parking, valet parking, car storage, or other places with attendant. Operation can be easily made by a key switch panel on control arm.

- Lifting capacity 2700kg or 2300kg.

- Car heights on ground up to 2050mm.

- Platform width up to 2500mm.

- Lifting height adjustable by limit switch

- Electric auto lock release enables easier operation.

- 24v control voltage avoids electric shock

- Galvanized platform, high-heel friendly

- Bolts & nuts passing 48hrs Salt Spray Test.

- Driven by hydraulic cylinder + Korean lifting chain

- Synchronization chain keeps platform level under all conditions

- Akzo Nobel powder coating provides long lasting surfificial protection

- Proven high end quality with CE certifificate, tested by TUV.

| Model | Hydro-Park 1127 | Hydro-Park 1123 | Hydro-Park 1120 |

| Lifting capacity | 2700kg /6000lbs | 2300kg /5000lbs | 2000kg/4400lbs |

| Lifting height | 2100mm /6'10" | 2100mm /6'10" | 1850mm /6'1" |

| Usable platform width | 2100mm /6'10" | 2100mm /6'10" | 2200mm /7'3" |

| Outer width | 2547mm /8'4" | 2547mm /8'4" | 2540mm /8'4" |

| Application | SUV+SUV | SUV+Sedan | Sedan+Sedan |

| Power pack | 2.2Kw | ||

| Power supply | 100-480V, 50/60Hz | ||

| Operation mode | Key switch | ||

| Operation voltage | 24V | 24V | 220v |

| Safety lock | Dynamic anti-falling lock | Dynamic anti-falling lock | Positioning lock |

| Lock release | Electric auto release | ||

| Lifting time | <55s | <55s | <35s |

| Finishing | Powdering coating | ||

Model HP1123 / HP1127

Model HP1123 / HP1127

This parking lift is hydraulic driven, with simple and reliable structure. The features of easy operation and long service life make it widely welcomed by families, enterprises, auto manufacturing, and auto logistics companies, etc.

The largest manufacturer of simple car parking lifts in China

Professional Experienced Highly-responsible

TUV Rheinland

CE COMPLIANT, DIN EN 14010

CERTIFIED BY TUV RHEINLAND

Two capacity options: 2300kg or 2700kg

Lifting height adjustable according to ceiling height

Keyswitch/emergency stop button

Concrete slab acceptable

Case study: 4 units sharing, 5 posts only

Posts of HP1123 & HP1127 are designed symmetrically and can be shared by adjacent parking lifts.

When multiple lifts are installed and connected side by side, the first lift has complete structure (Unit A).

The rest unit(s) are incomplete and have one post only (Unit B), because they can borrow the right post of

former lift.

By sharing the post, they cover smaller area, enjoy stronger structure, and bring costs down.

Please check with our sales whether your site is suitable for post sharing and how much you can savel

The details are impeccable

01

UPGRADED &

THICKENED STEEL

Super strong structure with 5 years warrar

02

ANTI-FALLING LOCKS

MECHANICAL & SAFER

Protecting your vehicles all the way

up and down

03

NEWLY UPGRADED

POWER PACK

24v control voltage, ZERO risk of electric

shock

04

STRONGER CHAINS

MADE IN KOREA

Withstanding 7 times of rated capacity

05

05

PASSING 72 HRS

SALT SPRAY TEST

Excellent rust resistance