- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Hydro-Park 1127 & 1123 have emerged as the most sought-after parking stackers in the industry, with their superior quality firmly established by over 20,000 users over the past 10 years.

| Availability: | |

|---|---|

| Quantity: | |

HP1123 & 1127

Mutrade

These two-post parking lifts present a simple yet highly cost-effective solution for creating 2 dependent parking spaces stacked one above the other. They are well-suited for a variety of settings, including permanent parking facilities, valet parking services, car storage areas, and other places where an attendant is present.

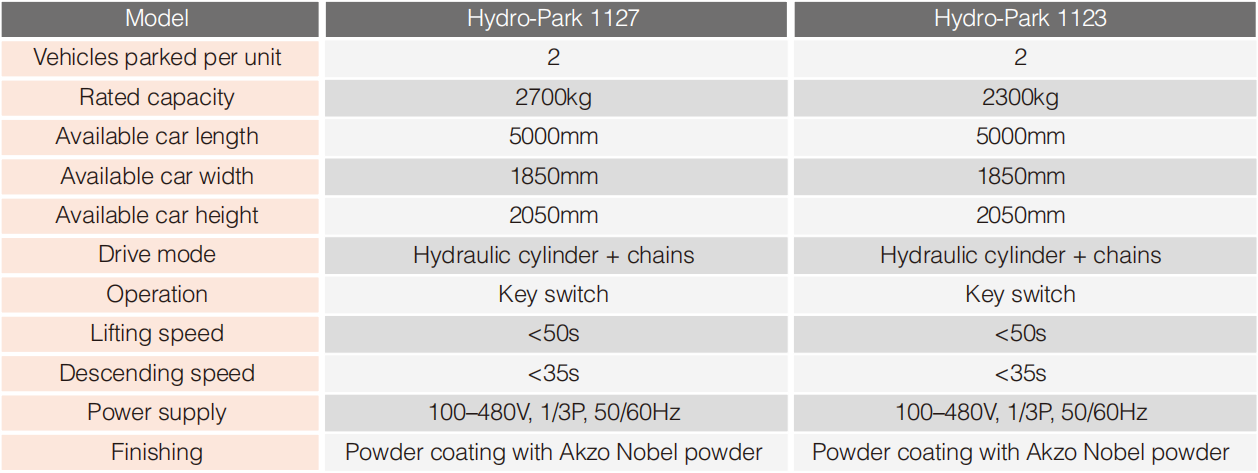

Operation of these stackers is straightforward, facilitated by a key switch panel on the control arm. The lifts come with a CE certificate tested by TUV, adhering to the certification standards 2006/42/EC and EN14010, which are recognized as some of the most authoritative in the world. This certification underscores the product's commitment to quality and safety.

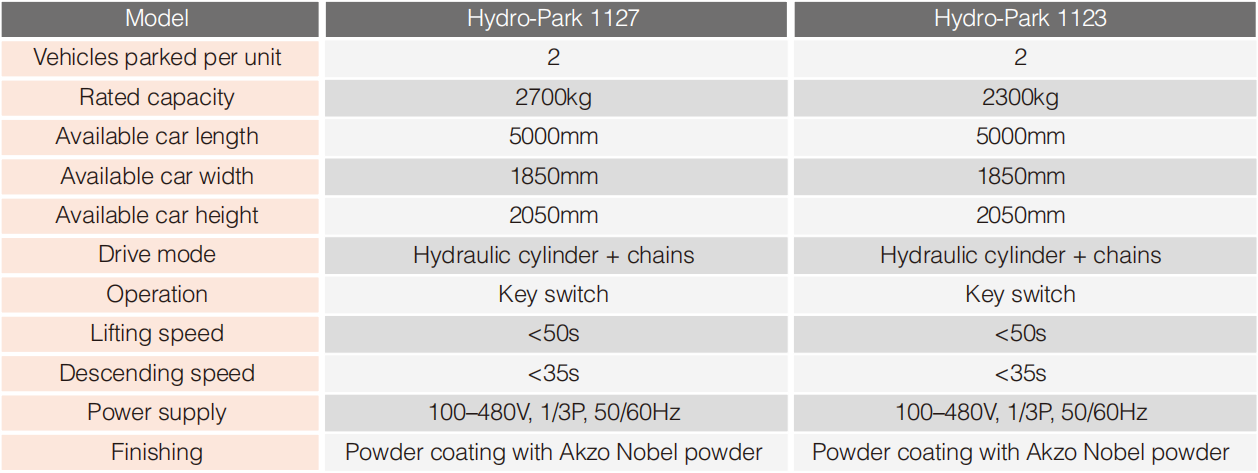

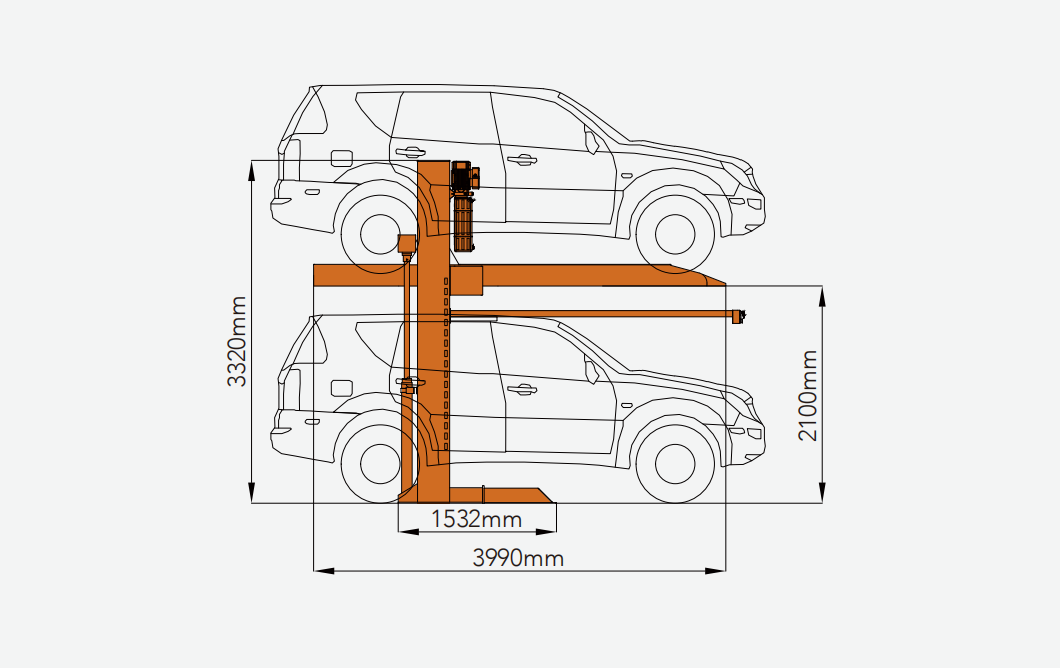

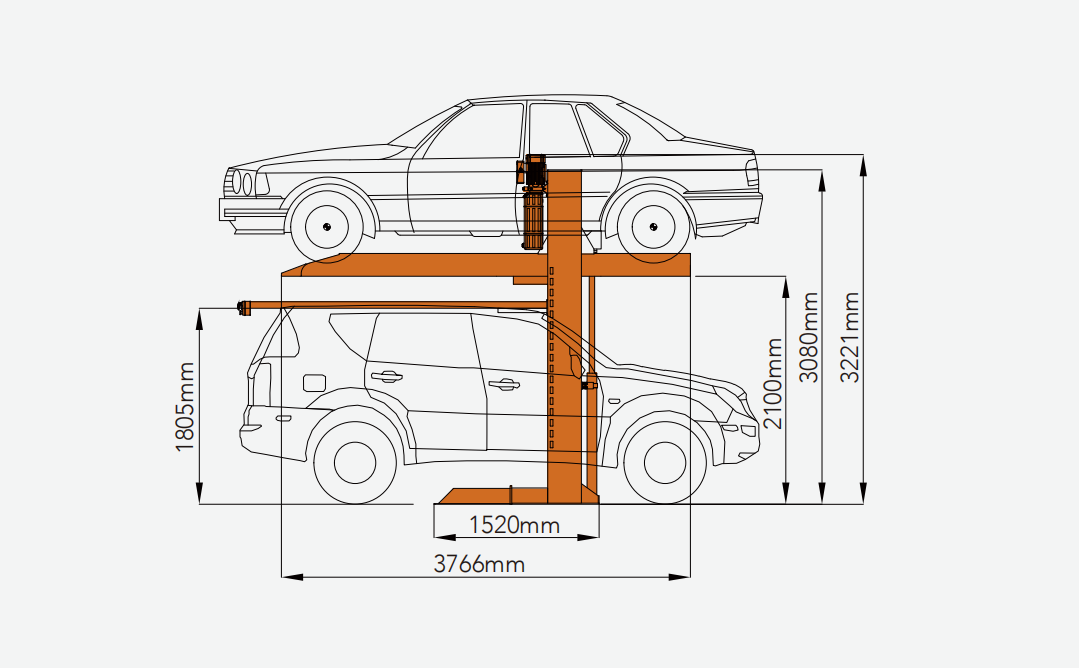

Lifting capacity of either 2700kg or 2300kg, ensuring they can accommodate a wide range of vehicle types.

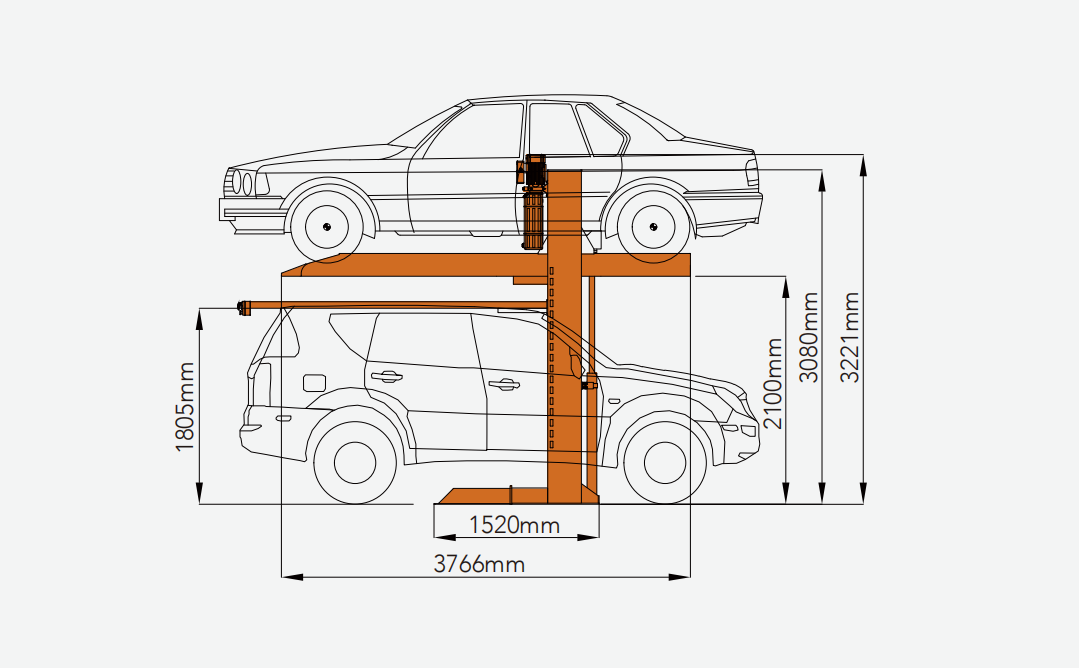

Cars on the ground can have a height of up to 2050mm, providing flexibility for different vehicle sizes.

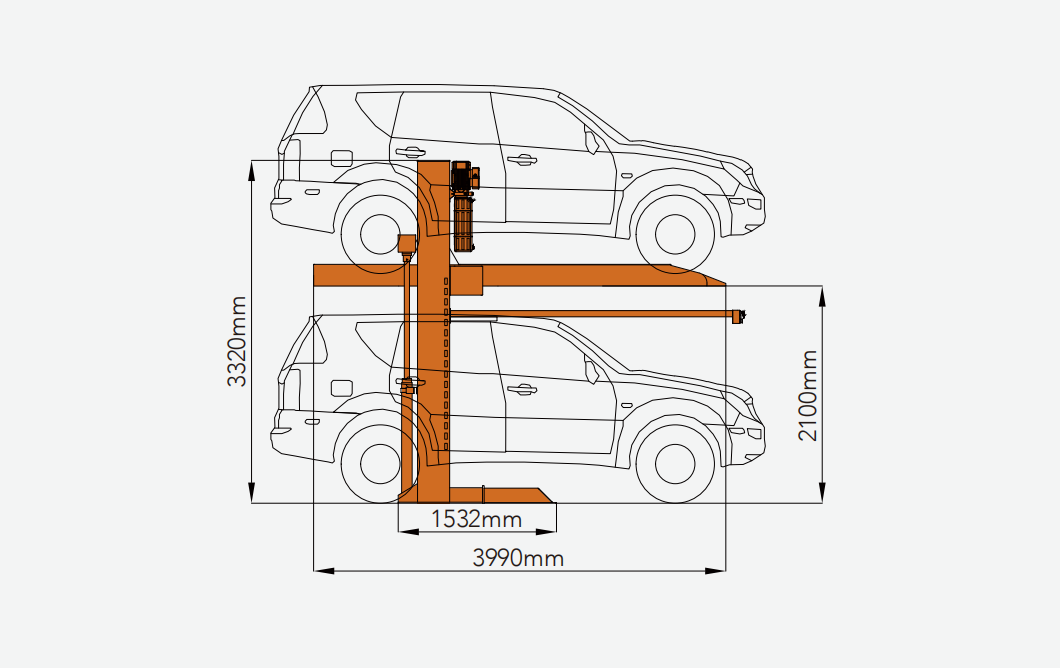

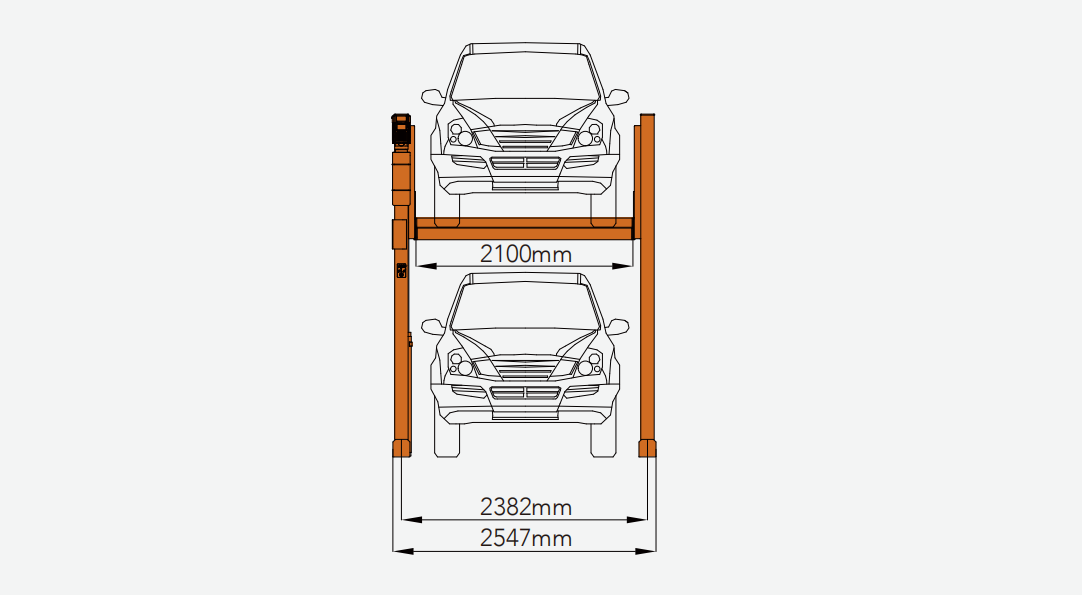

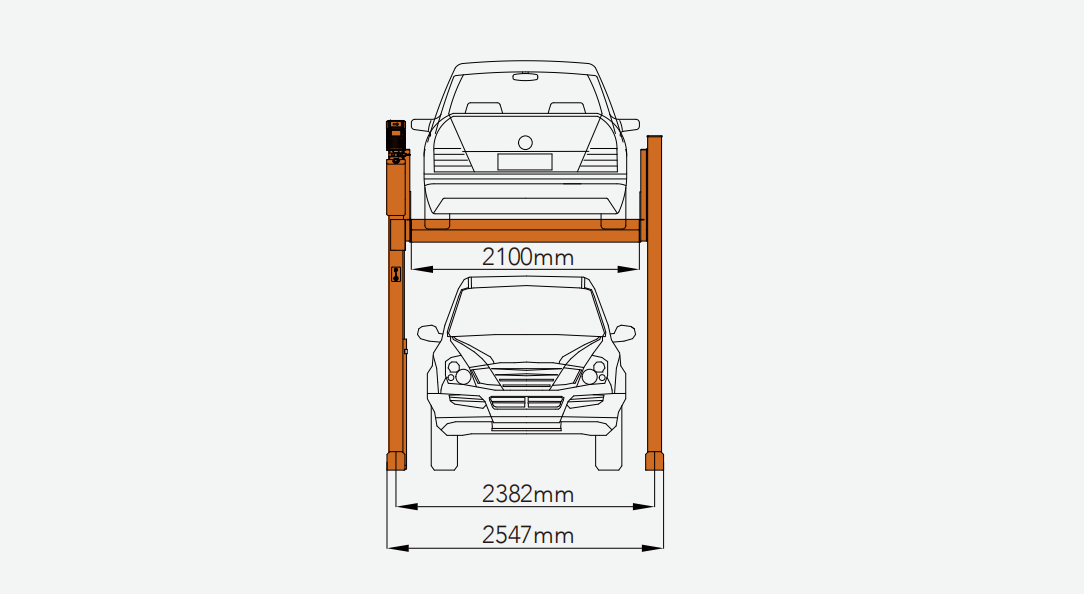

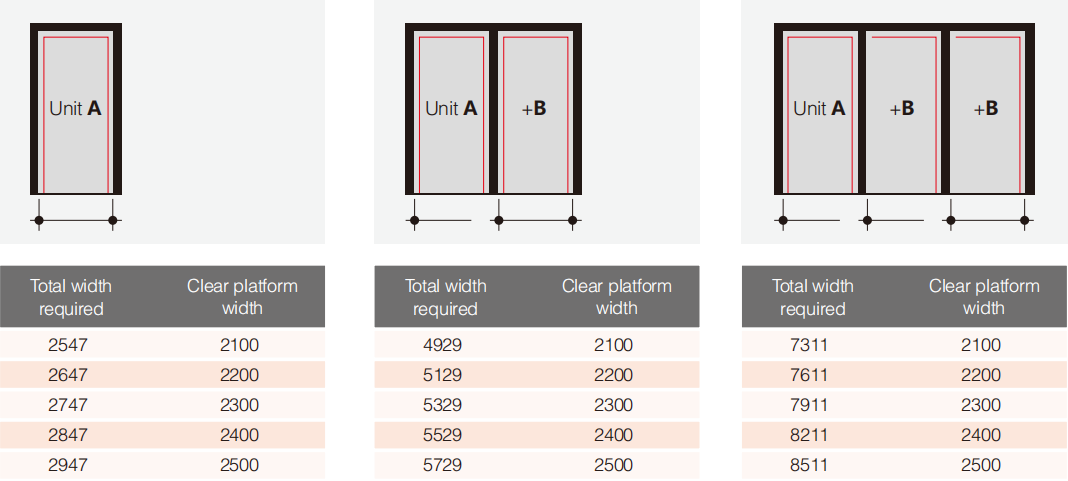

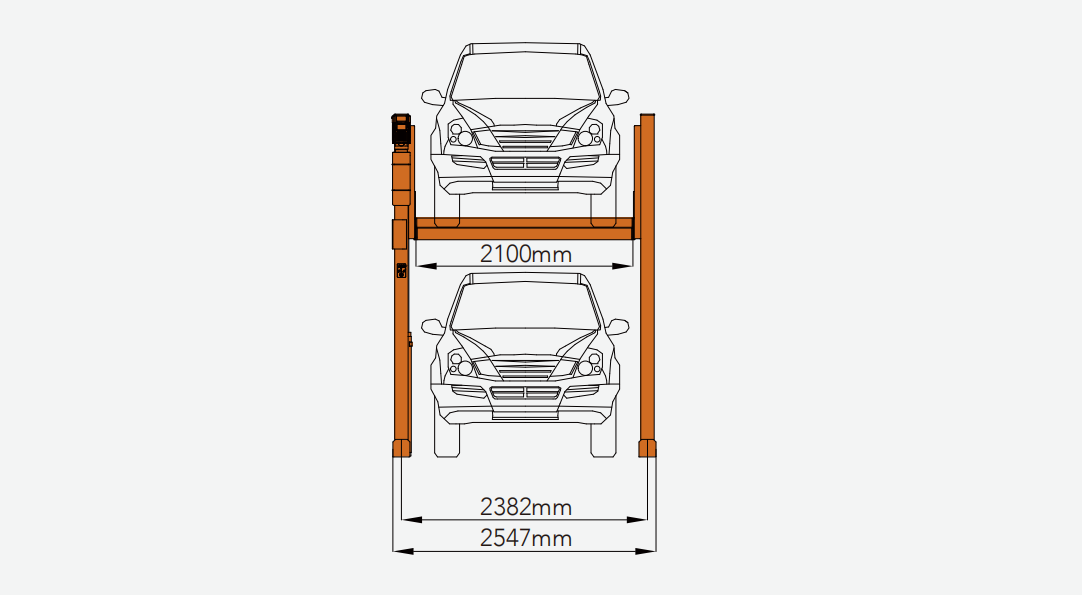

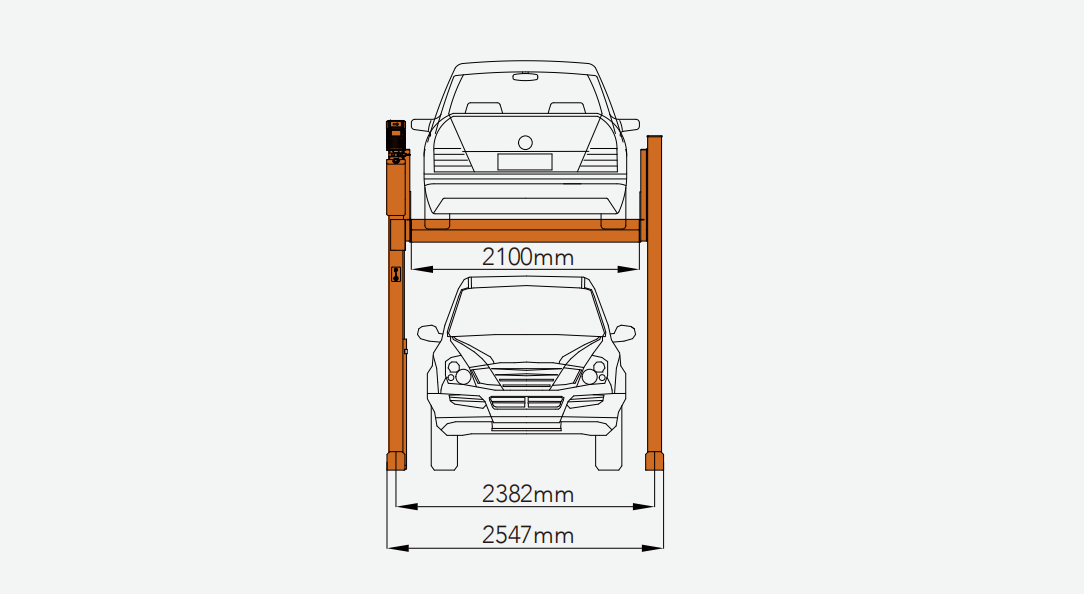

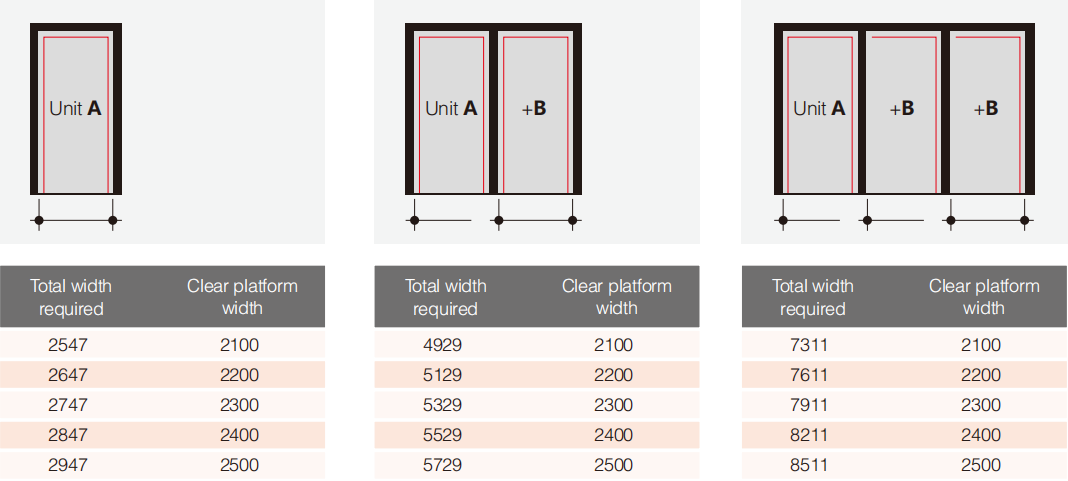

The platform width can reach up to 2500mm, with a clear platform width of 2100mm suitable for car widths of 1850mm. For larger touring sedans, a clear platform width of at least 2300-2500mm is recommended.

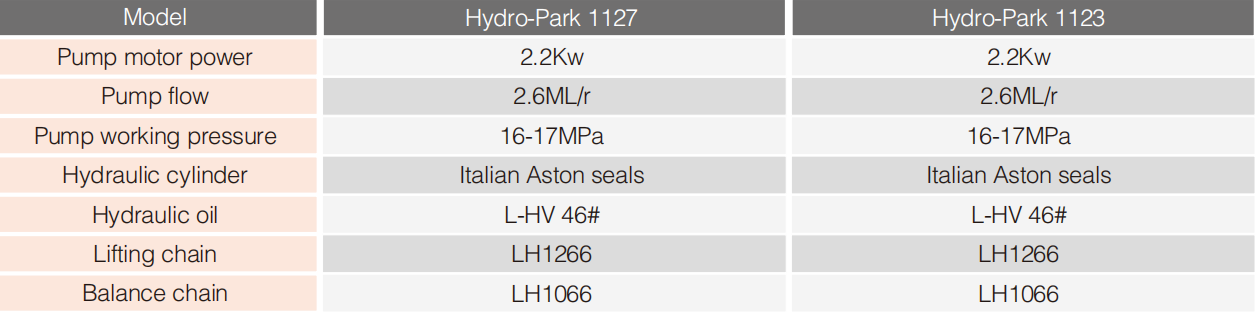

The lifting height is adjustable via a limit switch, allowing for customization based on specific needs.

Electric auto lock release simplifies operation, making it more user-friendly.

A 24v control voltage is used, eliminating the risk of electric shock and enhancing safety.

When the platform moves down, it is driven by gravity, resulting in no electricity consumption for the hydraulic power pack, thus reducing usage costs.

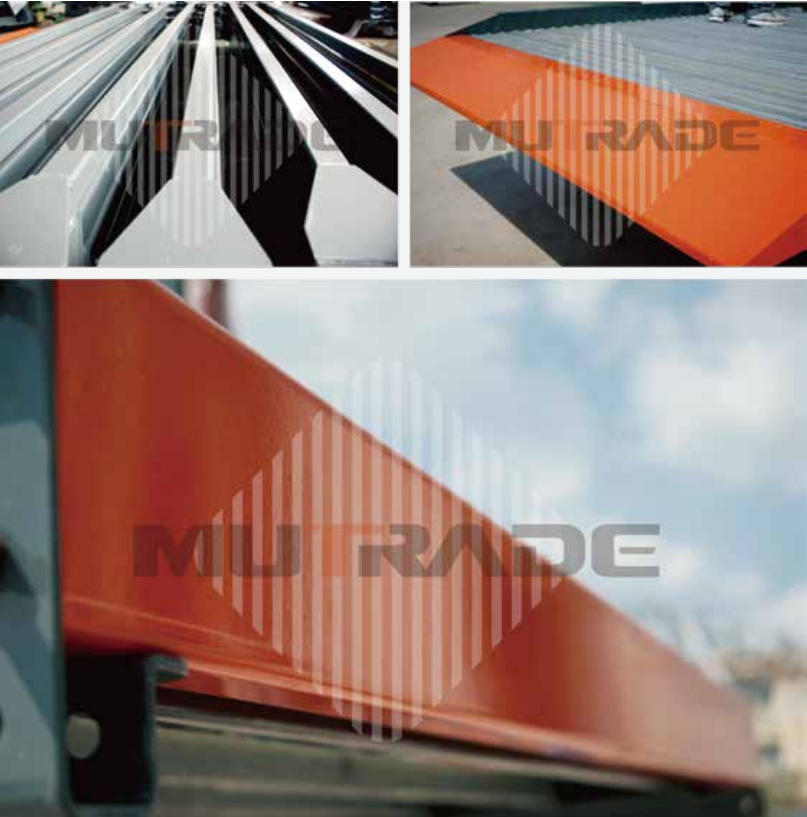

The platform is galvanized, making it high-heel friendly and far more beautiful and durable than conventional ones, with a lifetime more than doubled.

Bolts and nuts pass a 48hrs Salt Spray Test, ensuring excellent corrosion resistance and longer lifespan.

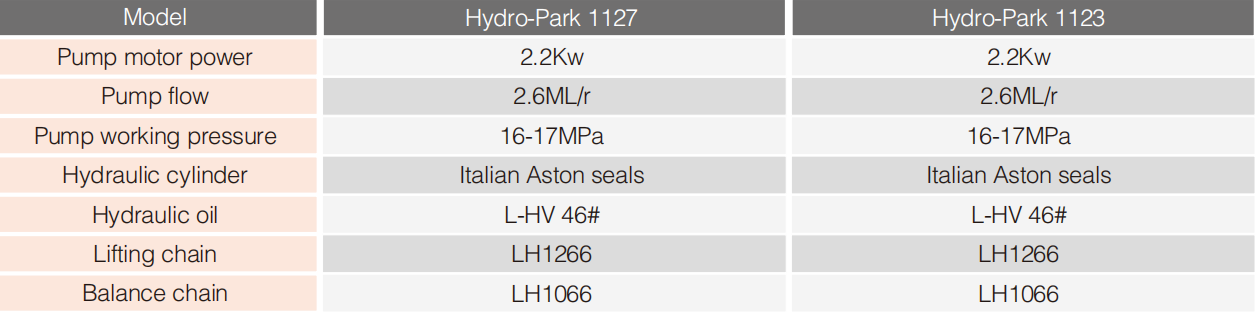

Driven by a hydraulic cylinder combined with a Korean lifting chain, the superior chains from a Korean manufacturer have a life span 20% longer than domestic chains.

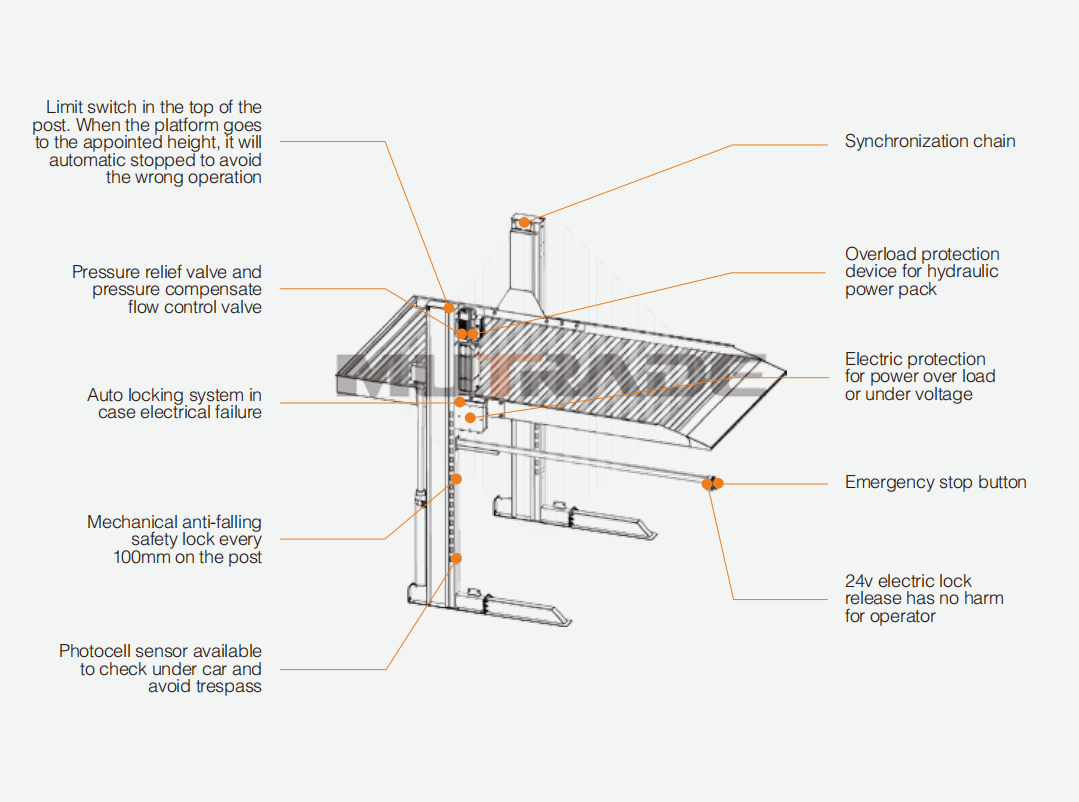

A synchronization chain keeps the platform level under all conditions, ensuring stable operation.

Akzo Nobel powder coating is applied, significantly enhancing color saturation, weather resistance, and adhesion, providing long-lasting surface protection. Great care is taken with the treatment of the lacquer face to maximize the product's surface quality.

Equipped with a dynamic locking device, featuring a range of locking tabs at every 100mm on the posts to prevent cars from falling, ensuring maximum safety.

All-new designed control system reduces the failure rate by 50%, making manipulation easier and use safer.

Optional unique hydraulic centralized control offers a perfect shared power pack unit solution.

Modular connection and innovative sharing post design (optional) allow combining multiple units at will based on usage requirements.

Hydro-Park 1127 & 1123 find extensive applications in various scenarios:

In residential areas, commercial buildings, and other places requiring long-term parking solutions, these stackers provide a stable and reliable option. Their durability and safety features ensure that vehicles are parked securely for extended periods.

Valet parking services benefit from the easy operation and space-saving design of these stackers. Attendants can efficiently park multiple vehicles in a limited space, improving service efficiency.

For car storage facilities, whether for personal car collections or commercial storage, the stackers offer a space-efficient way to store vehicles. The adjustable lifting height and platform width accommodate different types of stored cars.

In places such as hotels, resorts, and event venues where attendants manage parking, these stackers help optimize parking space utilization, ensuring that more vehicles can be parked in the available area.

Hydro-Park 1127 & 1123 hold the CE certificate tested by TUV, complying with the certification standards 2006/42/EC and EN14010, which are highly authoritative in the industry.

The lifting capacity is either 2700kg or 2300kg, allowing them to handle a variety of vehicles.

The floor must be flat and solid. According to ISO 3864, the floor has to be marked with 100mm wide yellow-black at a distance of 500mm from the platform edge by the purchaser, following local regulations. It is not possible to have channels or undercuts and/or concrete haunches along the floor-to-wall joints. If such channels or undercuts are necessary, the system width needs to be reduced or the installation width needs to be wider.

Clear platform width of 2100 mm for car widths of 1850 mm. For large touring sedans we recommend a clear platform width of at least 2300-2500 mm. According to ISO 3864 the floor has to be marked with 100 mm wide yellow-black at a distance of 500 mm from the platform edge by the purchaser (to be performed according to local regulations.) The lowering speed of an empty platform is considerably lower than a loaded one. It is not possible to have channels or undercuts and/or concrete haunches along the floor-to-wall joints. It the event that channels or undercuts are necessary, the system width needs to be reduced or the installation width needs to be wider. The manufacturer reserve the right to construction or model modifications and/or alterations. Furthermore, the right to any subsequent part modification and/or variations and amendments in procedures and standards due to technical and engineering progresses in the art or due to environmental regulation changes, are also hereby reserved.

These two-post parking lifts present a simple yet highly cost-effective solution for creating 2 dependent parking spaces stacked one above the other. They are well-suited for a variety of settings, including permanent parking facilities, valet parking services, car storage areas, and other places where an attendant is present.

Operation of these stackers is straightforward, facilitated by a key switch panel on the control arm. The lifts come with a CE certificate tested by TUV, adhering to the certification standards 2006/42/EC and EN14010, which are recognized as some of the most authoritative in the world. This certification underscores the product's commitment to quality and safety.

Lifting capacity of either 2700kg or 2300kg, ensuring they can accommodate a wide range of vehicle types.

Cars on the ground can have a height of up to 2050mm, providing flexibility for different vehicle sizes.

The platform width can reach up to 2500mm, with a clear platform width of 2100mm suitable for car widths of 1850mm. For larger touring sedans, a clear platform width of at least 2300-2500mm is recommended.

The lifting height is adjustable via a limit switch, allowing for customization based on specific needs.

Electric auto lock release simplifies operation, making it more user-friendly.

A 24v control voltage is used, eliminating the risk of electric shock and enhancing safety.

When the platform moves down, it is driven by gravity, resulting in no electricity consumption for the hydraulic power pack, thus reducing usage costs.

The platform is galvanized, making it high-heel friendly and far more beautiful and durable than conventional ones, with a lifetime more than doubled.

Bolts and nuts pass a 48hrs Salt Spray Test, ensuring excellent corrosion resistance and longer lifespan.

Driven by a hydraulic cylinder combined with a Korean lifting chain, the superior chains from a Korean manufacturer have a life span 20% longer than domestic chains.

A synchronization chain keeps the platform level under all conditions, ensuring stable operation.

Akzo Nobel powder coating is applied, significantly enhancing color saturation, weather resistance, and adhesion, providing long-lasting surface protection. Great care is taken with the treatment of the lacquer face to maximize the product's surface quality.

Equipped with a dynamic locking device, featuring a range of locking tabs at every 100mm on the posts to prevent cars from falling, ensuring maximum safety.

All-new designed control system reduces the failure rate by 50%, making manipulation easier and use safer.

Optional unique hydraulic centralized control offers a perfect shared power pack unit solution.

Modular connection and innovative sharing post design (optional) allow combining multiple units at will based on usage requirements.

Hydro-Park 1127 & 1123 find extensive applications in various scenarios:

In residential areas, commercial buildings, and other places requiring long-term parking solutions, these stackers provide a stable and reliable option. Their durability and safety features ensure that vehicles are parked securely for extended periods.

Valet parking services benefit from the easy operation and space-saving design of these stackers. Attendants can efficiently park multiple vehicles in a limited space, improving service efficiency.

For car storage facilities, whether for personal car collections or commercial storage, the stackers offer a space-efficient way to store vehicles. The adjustable lifting height and platform width accommodate different types of stored cars.

In places such as hotels, resorts, and event venues where attendants manage parking, these stackers help optimize parking space utilization, ensuring that more vehicles can be parked in the available area.

Hydro-Park 1127 & 1123 hold the CE certificate tested by TUV, complying with the certification standards 2006/42/EC and EN14010, which are highly authoritative in the industry.

The lifting capacity is either 2700kg or 2300kg, allowing them to handle a variety of vehicles.

The floor must be flat and solid. According to ISO 3864, the floor has to be marked with 100mm wide yellow-black at a distance of 500mm from the platform edge by the purchaser, following local regulations. It is not possible to have channels or undercuts and/or concrete haunches along the floor-to-wall joints. If such channels or undercuts are necessary, the system width needs to be reduced or the installation width needs to be wider.

Clear platform width of 2100 mm for car widths of 1850 mm. For large touring sedans we recommend a clear platform width of at least 2300-2500 mm. According to ISO 3864 the floor has to be marked with 100 mm wide yellow-black at a distance of 500 mm from the platform edge by the purchaser (to be performed according to local regulations.) The lowering speed of an empty platform is considerably lower than a loaded one. It is not possible to have channels or undercuts and/or concrete haunches along the floor-to-wall joints. It the event that channels or undercuts are necessary, the system width needs to be reduced or the installation width needs to be wider. The manufacturer reserve the right to construction or model modifications and/or alterations. Furthermore, the right to any subsequent part modification and/or variations and amendments in procedures and standards due to technical and engineering progresses in the art or due to environmental regulation changes, are also hereby reserved.